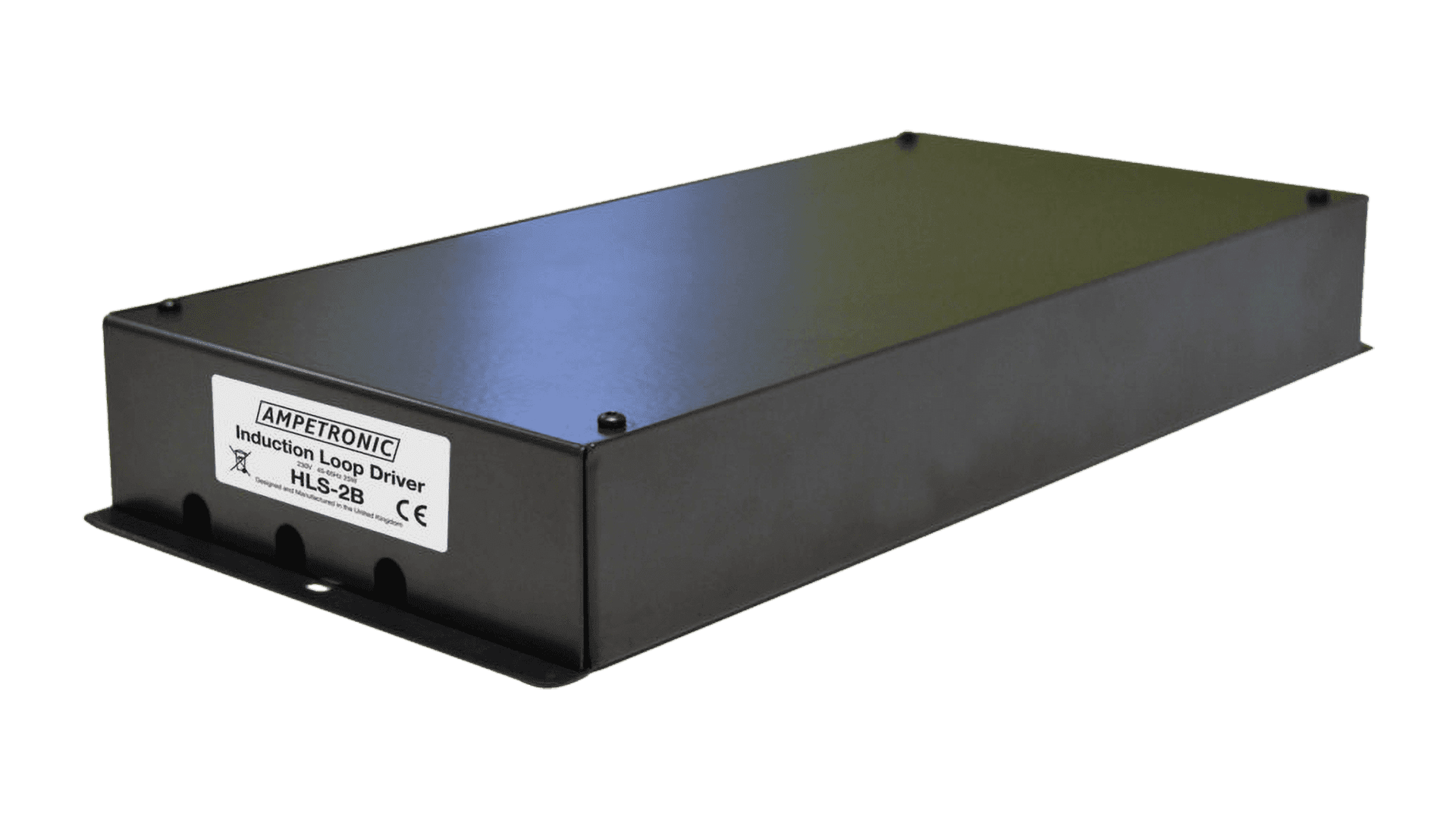

The HLS series units feature efficient class D current drive technology to reduce power consumption and heat output and are the only small area induction loop solutions capable of reliably driving most practical small area loops in high metal environments to meet the IEC60118-4

Standard. The amplifier enclosure is constructed of a robust steel housing and the solution features a battery back-up in the the event of a power failure that will provide 12 hours of standby time and 2 hours in full operation. It is further protected by a 5 year warranty from Ampetronic. The magnetic field strength and distribution in a lift car will be highly dependent on installation method and the construction of the lift car. It is strongly recommended that you contact Ampetronic for free technical support and advice on the best methodology and design for your specific application.

- Compact & lightweight

- Class D Efficiency

- Unrivalled Intelligibility

- 2 transformer isolated inputs

- Simple Integration

- Full Area Coverage Lifts

- Metal loss correction

- Unrivalled intelligibility

- Low lifetime cost

- Excellent reliability, 5 year warranty & free technical support (NOTE battery is only covered by 1 year warranty)

- 1:1 Potential area coverage of up to 36m2 Single turn 2.5mm wire floor level loop @ 1:1 ratio, 2m feed cable, no metal loss

- 3:1 Potential area coverage of up to 29m2 Single turn 2.5mm wire, floor level loop @ 3:1 ratio,2m feed cable, no metal loss

- 1:1 Practical lift application area coverage of up to 16m2 Ceiling mounted lift bars @ 2.1m height, 1m feed cable, 12dB metal loss

- 1:1 Practical lift application area coverage of up to 12m2 Ceiling mounted lift bars @ 2.1m height, 2m feed cable, 12dB metal loss

INPUTS

Power Supply

| Supply Voltage range: |

90-264V AC (Mains) |

| Fuse: |

630mA (230V)

1AT (120V) |

| Power Consumption: |

230V AC Supply into rated load

1.5mm2 solid core or untinned fine stranded wire. |

| Indication: |

LED on PCB |

| Connector: |

Fused screw terminal |

Input 1 & 2

| Connector: |

Wago 264 cage clamp for 0.78 – 2.5mm2 solid core or untinned fine stranded wire |

OUTPUTS

Loop Output

| Connector: |

Wago 264 cage clamp for 0.78 – 2.5mm2 solid core or untinned fine stranded wire |

| Compliance voltage: |

1.1VRMS (1.6Vpk) |

| Max output current (sine): |

11ARMS |

| Rated time for delivery: |

1min |

| Rated temperature limited output current (pink): |

6ARMS |

| Rated THD: |

<1% |

| Output Impedance: |

>1Ω |

| Current Adjustment: |

Full range |

| Current Indication: |

LED indicates >3ARMS |

Loop Impedance

0.1Ω to 0.2Ω, 0.14Ω reactive at 1.6 KHz

AUDIO SYSTEM

| Freq. Response |

100Hz to 5kHz ±1.5dB relative to 1kHz at low level, measured as loop current with no metal loss correction. |

| Compression (AGC) |

Time constants optimised for speech

(AGC) Dynamic range: >36dB

Control: by adjusting input level/gain

Indication: LED on PCB |

| Metal Loss Correction |

0dB to 3dB / octave boost |

| Correction |

Adjustable |

PHYSICAL

| Weight |

3kg |

| Environment |

IP22: <90% relative humidity, -20 to +50 °C (battery float life derates by 4% per °C above 25°C) |

| Dimensions |

Power Option: 230V AC

Width 158mm

Length 366mm

Height 49mm |

UP39501-3 HLS-2B datasheet 659

UP19501-3 HLS-2B